INTRODUCTION

The precision engineering and metrology group performs applied research on advanced manufacturing scenarios. From the development of challenging scientific and metrology instruments to the integration of existing technologies for the improvement of manufacturing processes. The group´s expertise relies on the extensive knowledge of industrial metrology from the micro-nano range to the large scale, combined with Tekniker´s vast knowledge about manufacturing processes, complex mechatronic systems, and all the areas involved within industrial engineering. A dimensional metrology laboratory (ENAC accredited) is included within the group´s technical expertise

SKILLS

- Micro-nano metrology

- IA based metrology

- Dimensional metrology laboratory

- Robotics

- Large-scale metrology

- Machine tools

- Photogrammetry

- Development of measurement procedures

- Laser tracker-based application development

- Optical 3D systems

- Industrial surveying

- Automation

- NDT based inspection

- Artificial Intelligence

PROJECTS

Some ongoing and past research projects:

INTER Q

In collaboration with 25 partners and led by IDEKO, InterQ is a European project whose main objective is to measure, predict and control the quality of the manufactured products, manufacturing process, and gathered data to assure Zero-Defect-Manufacturing by means of AI-driven tools powered with meaningful and reliable data.

PRECITEK

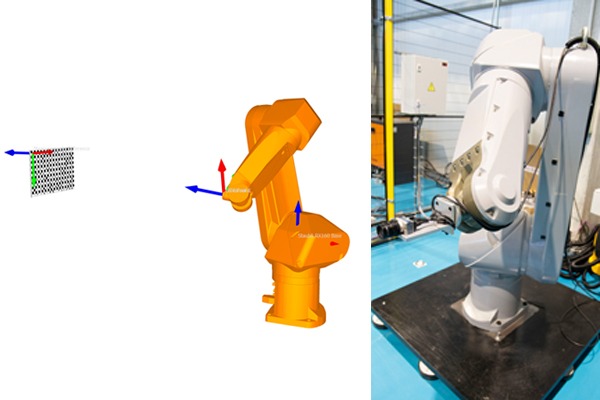

A local research initiative to collaborate within the precision engineering and metrology fields focused on the improvement of accuracy for machine tools and robots. The research aims at the development of accurate metrology digital twins. In collaboration with IDEKO, TECNALIA, UPV-EHU, IMH and VICOMTECH.

PRECISION 4.0

In collaboration with ZAYER machine tool builder, a new measurement method based on laser tracker technology is developed for the accurate and agile assembly of large machine tools by the assembly technicians replacing the traditional direct measurement tools.

MULTILINK INSPECTION TOOL

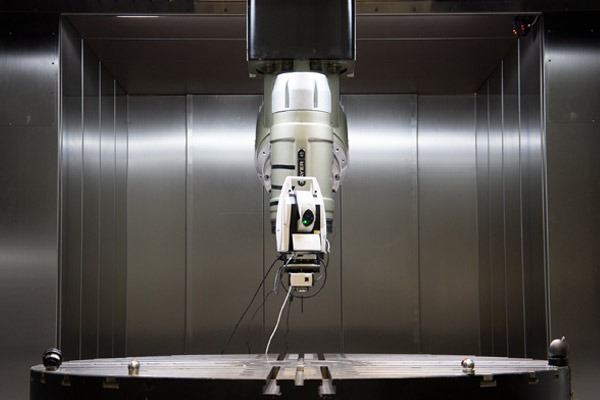

In collaboration with Fusion for Energy (F4E) a customized measurement instrument has been developed, the so-called Multilink Inspection Tool (MIT) to assess the geometrical tolerances of the Divertor multilink hinge at the ITER fusion reactor prototype.

INNOTOOL

Is a CLEAN-SKY European project for the purpose of developing smart 4.0 tools to improve the manufacture of thermoplastic parts and the assembly of aeronautical products. This initiative meets the requirements of the high-accuracy smart assembly process (SMART) defined by AERNNOVA, a top-level supplier of high-added value aeronautical structures. This organization has proposed, in coordination with AIRBUS, CS2 JU (Clean Sky 2 Joint Undertaking), a technological development topic for an “Advanced Rear End” demonstrator.

FACILITIES AND TECHNOLOGIES

The group has access to the state of art facilities and 3D metrology:

Dimensional metrology lab (ENAC accredited)

Ultra-precision lab

Assembly and manufacturing shop floor, including:

Laser tracker and laser tracer (6 dof)

Photogrammetry

3D scanning systems

CMMs

SA, Metrolog X4

Electronic microscopes, SEM, Atomic microscope

SOME OF OUR PEOPLE

- Dr. Gorka Kortaberria

- Dr. Mikel Armendia

- Dr. Eneko Gómez Acedo

- Dr. Iker Garmendia

- Brahim Ahmed

- Jon Eguskiza

- Fernando Egaña

- Ibon Vega

- Dr. Unai Mutilba

- Antonio Gutiérrez

- Jorge Molina

- Jesús Paredes

COLABORATORS

INDUSTRIAL PARTNERS

Zayer

Fagor

Aernnova

Siemens – Gamesa

Geminis

Hispavista

Etalon AG

SCIENTIFIC PARTNERS

CEM, PTB and NPL

RWTH Aachen and UCL

Hexagon Manufacturing Intelligence

Ommatidia

Sensofar

Ideko

Tecnalia

UPV - EHU