Taraz Metrology provides optical measurement solutions across different industries, including automobile, aerospace, metal manufacturing and composites manufacturing.

Leveraging extensive industrial experience and exceptional academic knowledge, we have developed a range of advanced optical metrology products. Powered by our proprietary TarazSharp software, we ensure smooth user experience throughout each stage of our processes from measurements to decision-making.

Our advanced solutions are traceable, and all metrology characteristics of our systems are calculated following NPL guidelines and ISO standards. Our successful case studies highlight our capability in measuring precise tolerances and complex surfaces and forms across various industries.

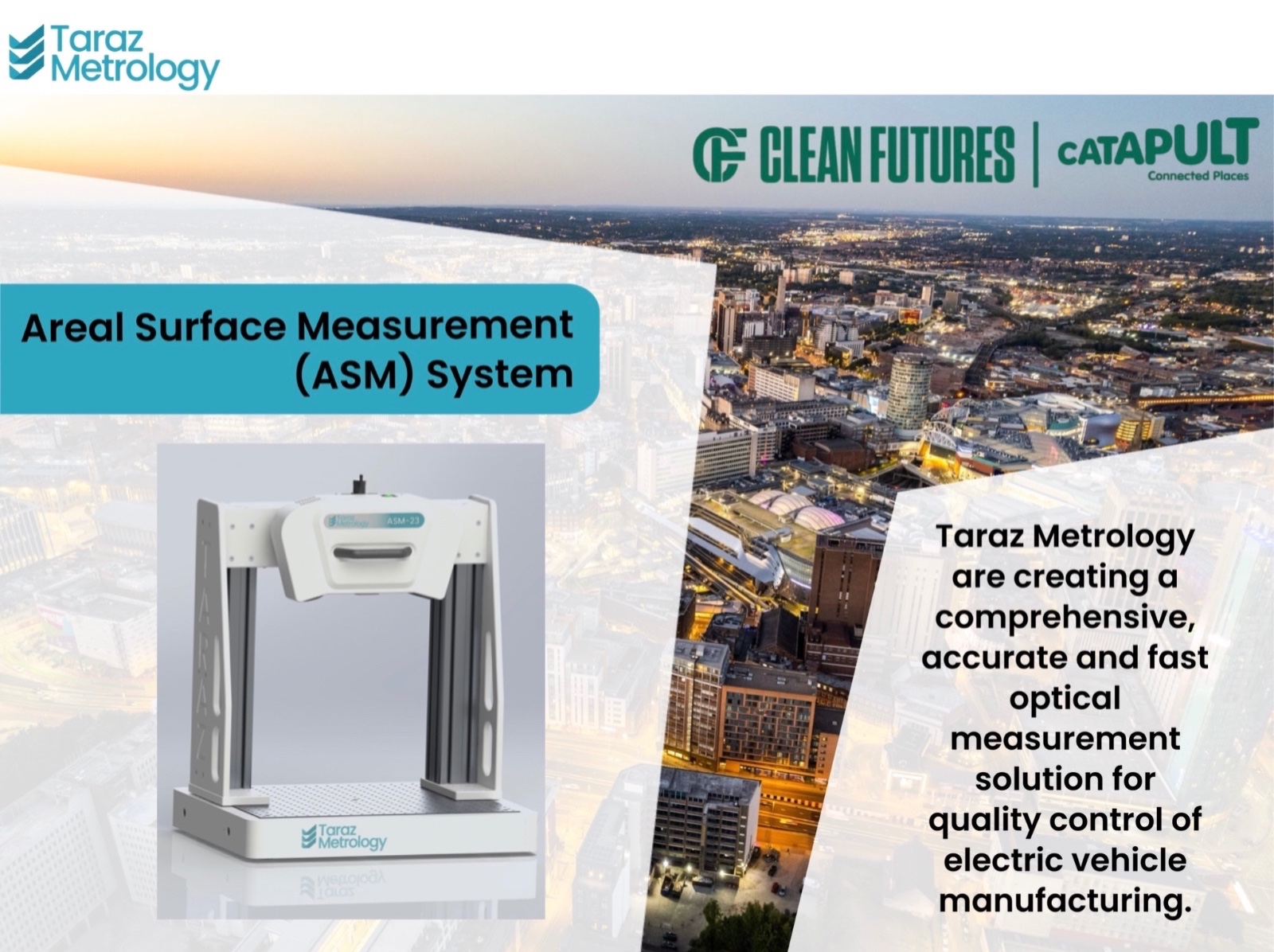

Fringe Projection

The ASM System is Taraz’s most advanced blue-light fringe projection system engineered for surface and topography measurements.

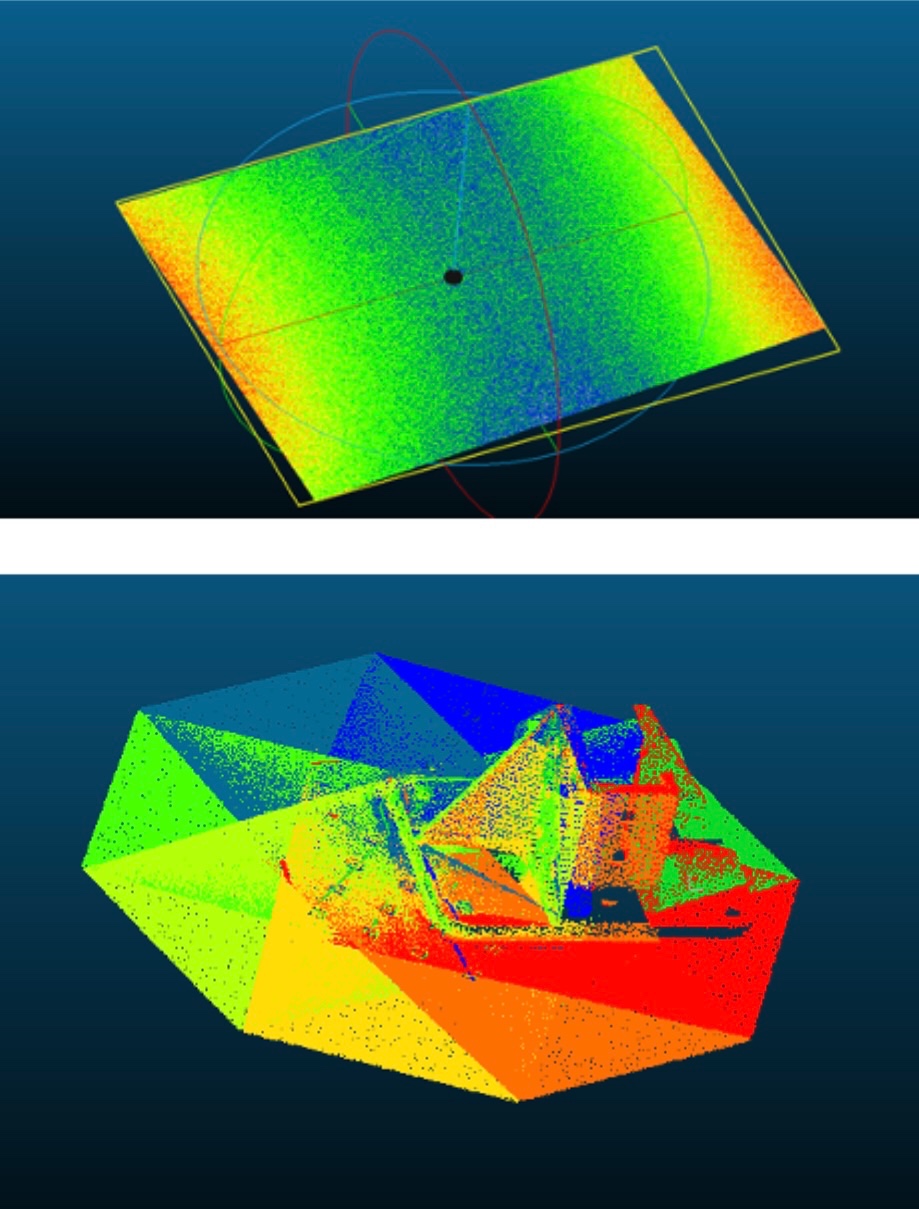

Laser Profilometry

The EPS is an optical measurement system that can accurately measure the surface of extruded metal billets in real-time, with accuracy down to 20 micrometers (depending on measurement size).

Multi-sensor System

The PM System is a versatile optical metrology solution designed for factory and shop floor environments. By integrating data from multiple sensors and viewpoints, it provides comprehensive, high-accuracy measurements across a wide range of materials.

Hardware and Software

At Taraz, we understand that every operation has unique requirements. Our hardware and software can be tailored to meet the specific needs of your application, ensuring seamless integration into your environment.

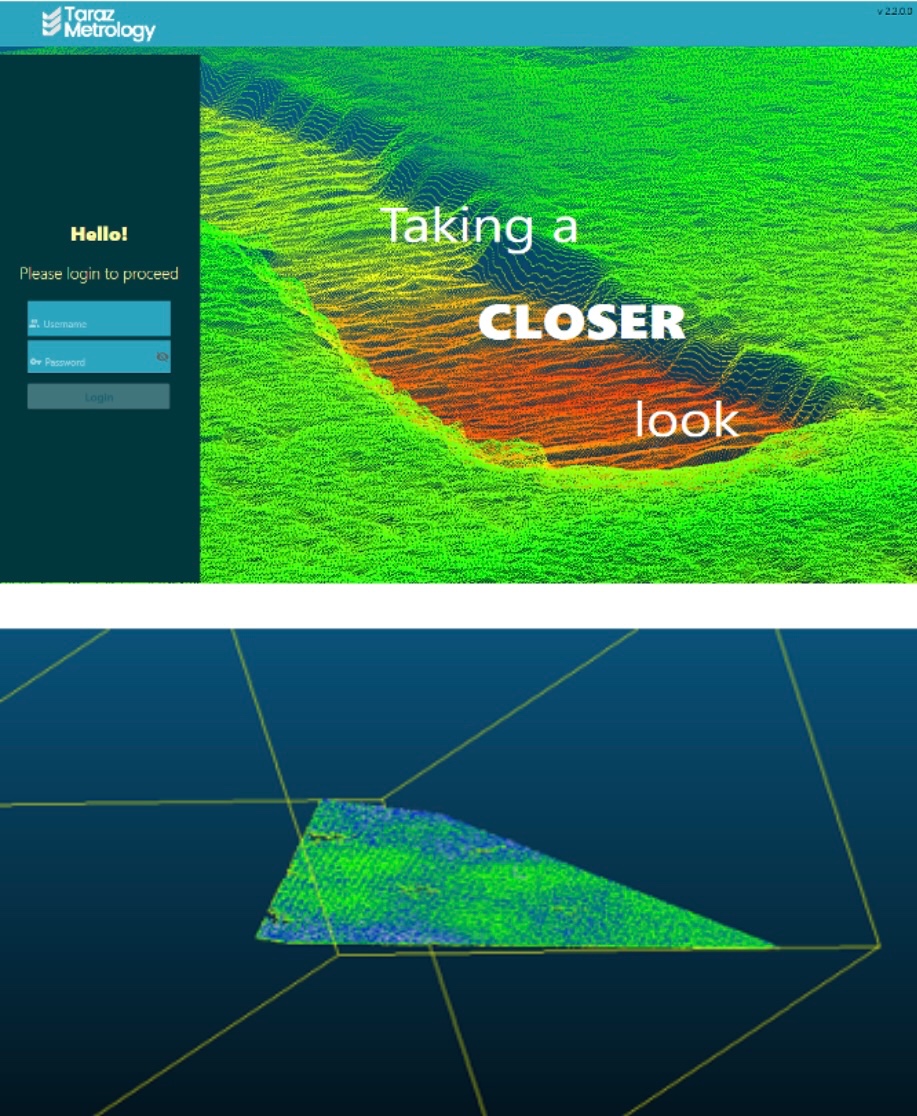

Software

TarazSharp is our proprietary software, designed to seamlessly integrate with all Taraz products. It includes surface measurements, equipment characterisation and flatness correction, ensuring accurate and reliable results.

We collaborate closely with renowned research institutions and manufacturing companies in aerospace, automobile and various other industries to drive innovation and ensure the highest level of performance and reliability.

Currently, we are working with Connected Places Catapult after winning the Clean Futures accelerator programme in the West Midlands. We also have close working relationships with the University of Nottingham and Coventry University, ensuring we always stay at the forefront of advances in the metrology industry.

We are actively engaged and highly skilled in a variety of advanced technology areas:

Talk To Us

We invite you to visit our offices to experience first-hand the capabilities and benefits of our advanced metrology solutions.

Phone:

+44(0) 115 906 1243

By connected places catapult

2024 - 2025

Developing new solutions to the challenges associated with the rail and automotive manufacturing sectors in the West Midlands to drive the Green Industrial Revolution, as part of a UK government backed programme.

We are currently working with a giant automobile manufacturer to create a comprehensive, accurate and fast optical measurement solution for quality control of electric vehicle manufacturing. Our innovative solution will be based on our existing ASM system.

Supported by european union

2021 - 2023

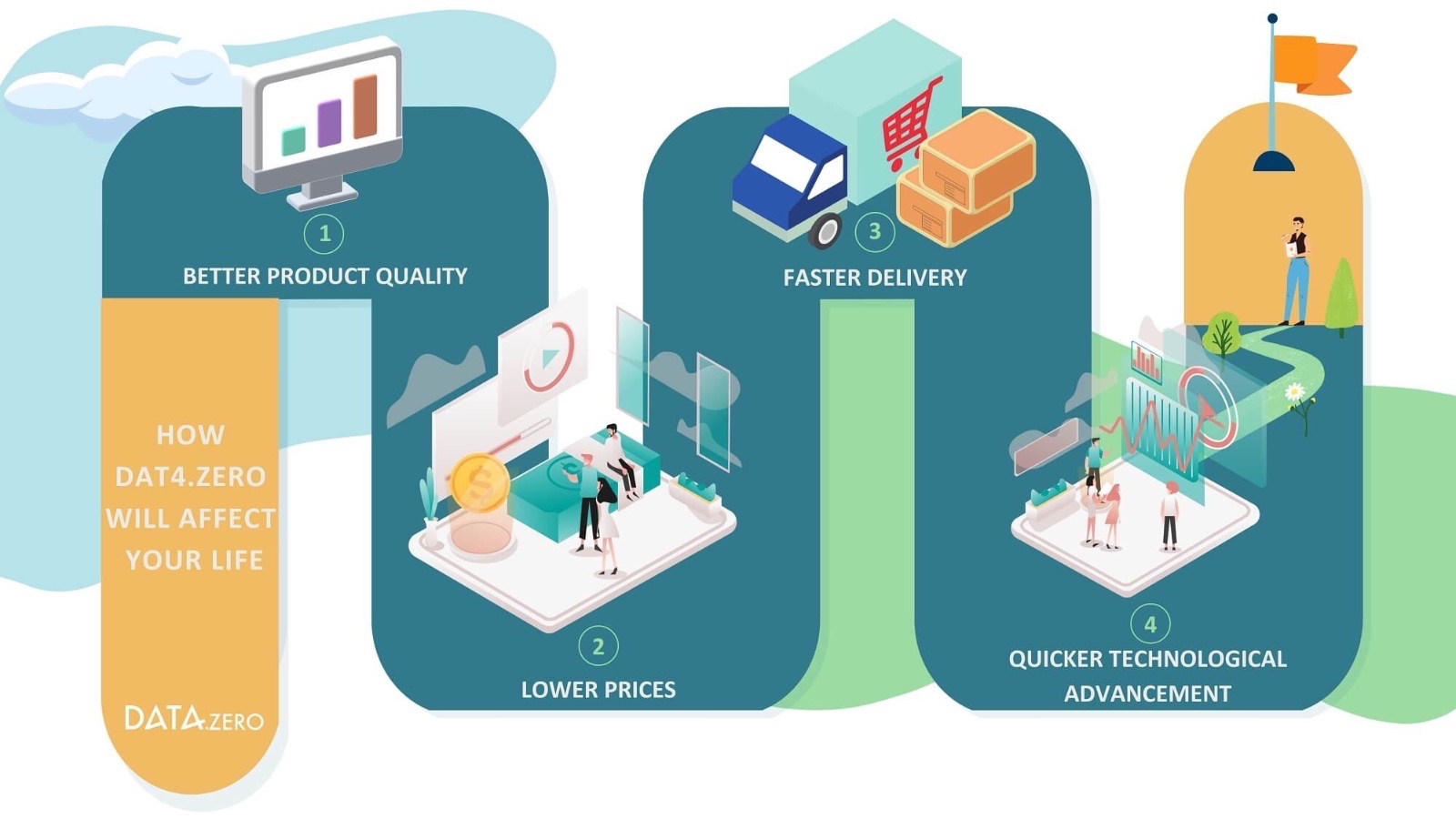

Development of innovative technologies to improve quality in European factories as part of DAT4Zero’s aim of revolutionising manufacturing processes.

Taraz has developed a solution to revolutionise in-line measurements of aluminium extrusions by using high-speed laser scanners and advanced software to measure the shape of the extrusion with extreme precision and accuracy in real-time, without causing any damage. This proactive approach to quality control significantly reduces waste, time and money in the manufacturing process while also improving product quality. Taraz has proven this technology can work by testing under laboratory conditions and developing advanced software for detecting shape error.

Our leadership team brings together expertise, innovation, and a commitment to developing unique solutions that meet the evolving client requirements. Each member plays a key role in driving our success and fostering an innovative culture.

A hands-on chairman and accomplished professional with a strong global business acumen through part ownership of 10 technology companies across 6 countries. Richard has a track record in managing successful technology companies and extensive experience in software engineering.

An entrepreneur with experience in establishing and growing tech businesses for an international audience. Waiel excels in people management, leading our team with a focus on innovation and efficiency. He has a proven track record of tackling complex challenges and delivering exceptional results as a metrology expert, with a PhD in Manufacturing Engineering.

A leader in metrology and professor at the University of Nottingham, with over 25 years experience in developing solutions with the National Physics Laboratory (NPL). Richard´s extensive experience and performance history in developing innovative solutions ensures that our technologies meet the highest accuracy and compliance standards.

An expert in metrology sales and marketing, with over 25 years experience in establishing strong industry relationships and driving growth. Matthew has a deep understanding of market dynamics and customer needs, enabling us to remain competitively positioned and profitable within the metrology industry.

Taraz Metrology was born out of the University of Nottingham’s Manufacturing Metrology Team, combining cutting-edge research and proven expertise.

We provide high-quality measurement solutions that play a critical role in quality assurance in production processes globally, driving efficiency and sustainability across industries.

With a focus on innovation, we provide flexible, high-speed, and accurate systems that integrates well with existing infrastructure.

Got a question or looking for more details? You can easily get in touch with us using our contact form below.